In the past we were always told to worry about strong winds when spraying. We now know that low wind conditions can be as bad or worse. New and reviewed herbicide labels since 2008 state that you must not spray during a surface temperature inversion.

What is a surface temperature inversion?

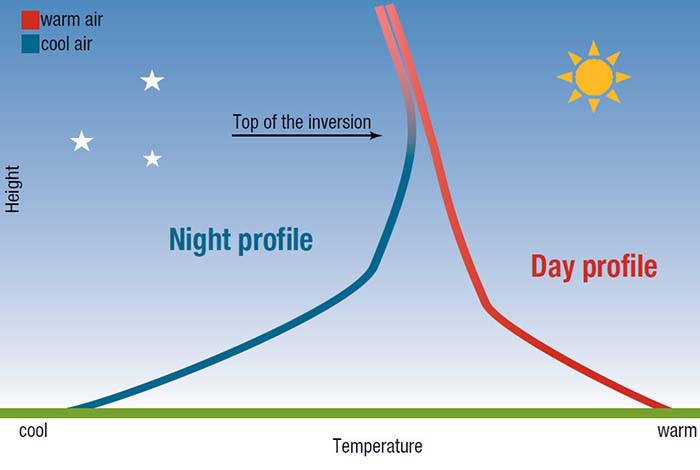

At sunset the ground loses heat and under low wind conditions air close to the ground cools while air above it is warmer. The air doesn’t mix and is described as being stable. Air temperature increases with height compared with during the day when air temperature most often decreases with height.

When this occurs close to the ground it is called a surface temperature inversion.

Typical inversion profiles during night and day. In an inversion the air warms to the top of the inversion. Source: G Tepper

Typical inversion profiles during night and day. In an inversion the air warms to the top of the inversion. Source: G Tepper

In a surface temperature inversion the point where the temperature stops increasing and begins to decrease is the top of the inversion layer. This is usually the top level of suspended particles such as dust, smoke and small spray droplets or vapour.

Note that these inversions can act as a barrier to regional winds which go over the top of the inversion preventing mixing of the air. This means that inversions can co-exist with higher wind speeds such as greater than 20 kph.

About 30 minutes after sunrise smoke from wood heaters not mixing and moving parallel to the ground due to a surface temperature inversion. Image: AGRONOMO

About 30 minutes after sunrise smoke from wood heaters not mixing and moving parallel to the ground due to a surface temperature inversion. Image: AGRONOMO

What is the big deal with surface temperature inversions?

In November-December 2015 large areas of sensitive crops in NSW and Queensland have been damaged by spray drift, largely through spraying during inversion conditions. See the APVMA press release http://apvma.gov.au/node/19546 saying they won’t take action at this point. Hmm.

Because inversions prevent the mixing of air, any suspended fine droplets and particles, including spray, can move off in any direction to be deposited up to 20 km away once the inversion breaks the next day.

Cold air drainage within the inversion will cause fine droplets and particles to accumulate in the low parts of the landscape.

Remember that spray drift creates a number of major issues including crop damage, damage to sensitive vegetation and contamination of water and produce. Have you signed a declaration saying that you haven’t applied certain chemicals? You might not have, however contamination could have occurred via drift and you could be paying the price through rejection of your product.

Visual clues to indicate the existence of an inversion

- Formation of mist or fog

- Smoke of dust hanging in the air and moving horizontally

- Flattening of clouds as evening approaches

As evening sets in fluffy (cumulus) clouds flattening is a sign of impending inversion formation. Don't mix another spray tank! Image:AGRONOMO

As evening sets in fluffy (cumulus) clouds flattening is a sign of impending inversion formation. Don't mix another spray tank! Image:AGRONOMO

Rules of thumb – Conditions necessary for inversions to form Source: National Working Party on Pesticide Application

- A reduction in wind speed to below 11 kph is necessary for all seasons.

- In summer, a fall of at least 4°C from maximum temperature recorded on the day promotes an inversion an hour after sunset.

- In winter, a fall of at least 2°C from the maximum temperature recorded on the day promote an inversion even an hour before sunset.

- If the difference between the observed maximum temperature and forecast minimum temperature is 10°C or more then there is a 90% risk of inversion conditions at sunrise.

Research funded by the GRDC is currently being conducted by Graeme Tepper and Warwick Grace to predict the formation of surface temperature inversions and assign risks for night spraying. The research is well advanced in Western Australia and will be continued in more complex terrain (i.e. not WA) over the next 12 months. Yes, WA is pretty flat.

Nufarm Spraywise Decisions™ and Syngenta’s Weather forecast are tools you should all be using for planning your spray program.